Maintenance instructions - TrustLink Stress Termination with Steel

General cleaning

Clean by rinsing the equipment, TrustLink and cable with fresh water at the end of each operation.The umbilical should be cleaned and re-lubricated at regular intervals, particularly before laying up. The cable may never ‘dry out’.

MacArtney can offer Masto pressure-lubricant systems, with pump and suitable seal-rings for the cable. As a lubricant, we recommend Gadus S3 Wire rope grease. Similar can be used. Biodegradable lubricant (compliant with US VGP EAL requirements) is also available.

General inspection

Regularly inspect the umbilical for damage, particularly on mobilisation and after operation.

The Steel Armoured Cable is protected against corrosion under production by a galvanic coating. During operations, this will be consumed and no longer provide protection for the steel and eventually, the wires will start to rust. To extend the lifespan of the cable, MacArtney recommends that the cable is fully greased.

If the armour near the termination appears to be irregular, this indicates that part of the umbilical is starting to fatigue. Small cross-section cores may soon break, and therefore the umbili- cal should be re-terminated before breaks occur.

It is recommended that the umbilical is re-terminated at inter- vals of no greater than two to three years, dependent on use.

Storage

Avoid storing in extreme temperatures and particularly in direct sunlight. If storing on a ship’s deck, protect from salt spray and preferably lubricate the armour prior to storage. All cables should be protected from exposure to oils, solvents or vapours that may damage the sheath materials.

Course of action

-

Inspection

After operation, inspect the cable, TrustLink and all components at the connection point for signs of wear or damage. -

Cleaning

Clean the TrustLink, cable and the back of the Bend Restrictor with fresh water. -

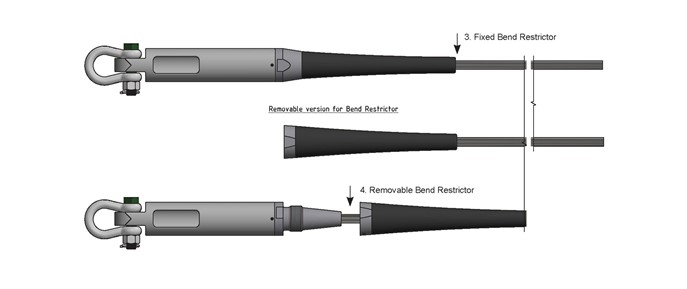

Fixed Bend Restrictor

Apply extra grease to the cable as needed and squeeze in additional grease between the cable and fixed Bend Restrictor. -

Removable Bend Restrictor

Regardless of how often the equipment is submerged, the Bend Restrictor must be regularly removed, cleaned with fresh water and greased, at least once a year.- Remove locking screws

- Detach the Bend Restrictor part. Clean all parts with fresh water

- Apply grease to the back of the cone part and onto the cable

- Reinstall the Bend Restrictor by using anti-seizing grease on the threads. To secure the locking screws, use Loctite 242 or a similar thread-locker. For daily maintenance, soft securing can be used as seawater grease, for example, Aqua Shield (Aqua Lube)

Note

All disconnected connectors must be protected with dust caps or dummy connectors to protect contacts. If in water, the connector must have a pressure protection cap.

To extend the service life of all steel-reinforced cables, we recommend always keeping the complete length of the cable greased.