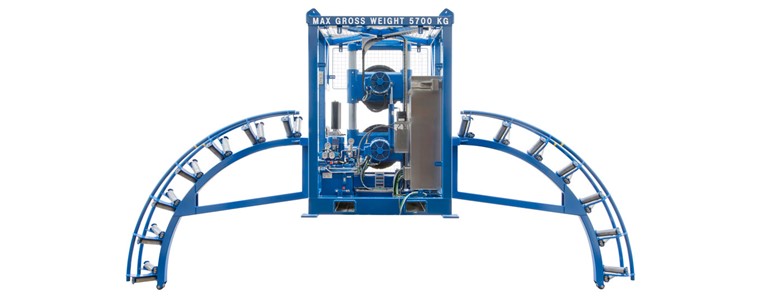

CEMAC Bow Cable Engines

Request a quote for: CEMAC Bow Cable Engines

Get your non-binding quote today and see how we can help.

The CEMAC Bow Cable Engines (BCEs) represent MacArtney’s leading-edge offshore cable handling equipment. These BCEs belong to the CEMAC product line and incorporate cable carousels, linear cable engines, and track tensioners. Being electrically driven, the CEMAC BCEs are accurate and energy-efficient systems that safely control the installation and recovery of offshore power and telecom cables.

The CEMAC BCEs feature durability, high performance, and easy integration. Available in standard and custom configurations, they are easily combined with cable carousels, track tensioners, spooling arms, etc.

The CEMAC design represents compact and modular systems being easily mobilised and cost-effective in terms of transport. All main components are standardised, facilitating adaptation and upgrading to the required performance and capacity.

The CEMAC BCEs are fully synchronisable with all CEMAC offshore cable handling equipment. The track tensioners also comply with third-party equipment, enabling integration into existing and rental cable equipment lay-lines.

The CEMAC BCEs are available with a remote diagnostics tool, which enables MacArtney technicians to monitor and supervise remotely in real-time. By eliminating unnecessary offshore engineering support, this unique feature generates substantial cost savings for owners and operators.

Versatility in all transpooling applications

CEMAC BCEs offer versatile functionality. By removing the bow arms, the BCEs can be operated as a Linear Cable Engine (LCE). This adaptability enables handling of both vertical and horisontal cable transpooling operations. CEMAC BCEs and LCEs seamlessly integrate with carousels and other third-party equipment. Available in 1-, 2-, and 3-wheel pair configurations, these engines are also suitable for master-slave operations, enhancing flexibility and efficiency.

Features and benefits

- Suitable to deploy as a Linear Cable Engine

- Compact and modular design

- Minimal pressurised oil

- Electrically driven, eliminating the necessity for external HPUs

- Small footprint

- Standardised and exchangeable components

- Optimised energy consumption

- Accurate controllability

- Integrated control system

- Designed for seamless system integration

- Advanced product integrity monitoring system

- Comprehensive data logging

- Low noise operation

- DNV/BV compliant design

Options

- Extra high speed 6000 m/hour

- Remote diagnostics

- Service and maintenance program

- Tailored spare parts philosophy

- Wireless remote control

- Comprehensive data output

- Tarpaulin cover

- CE marking

- Certification according to DNVGL-ST-0378 (2.22), DNVGL-E2.7-3, and ILO 152