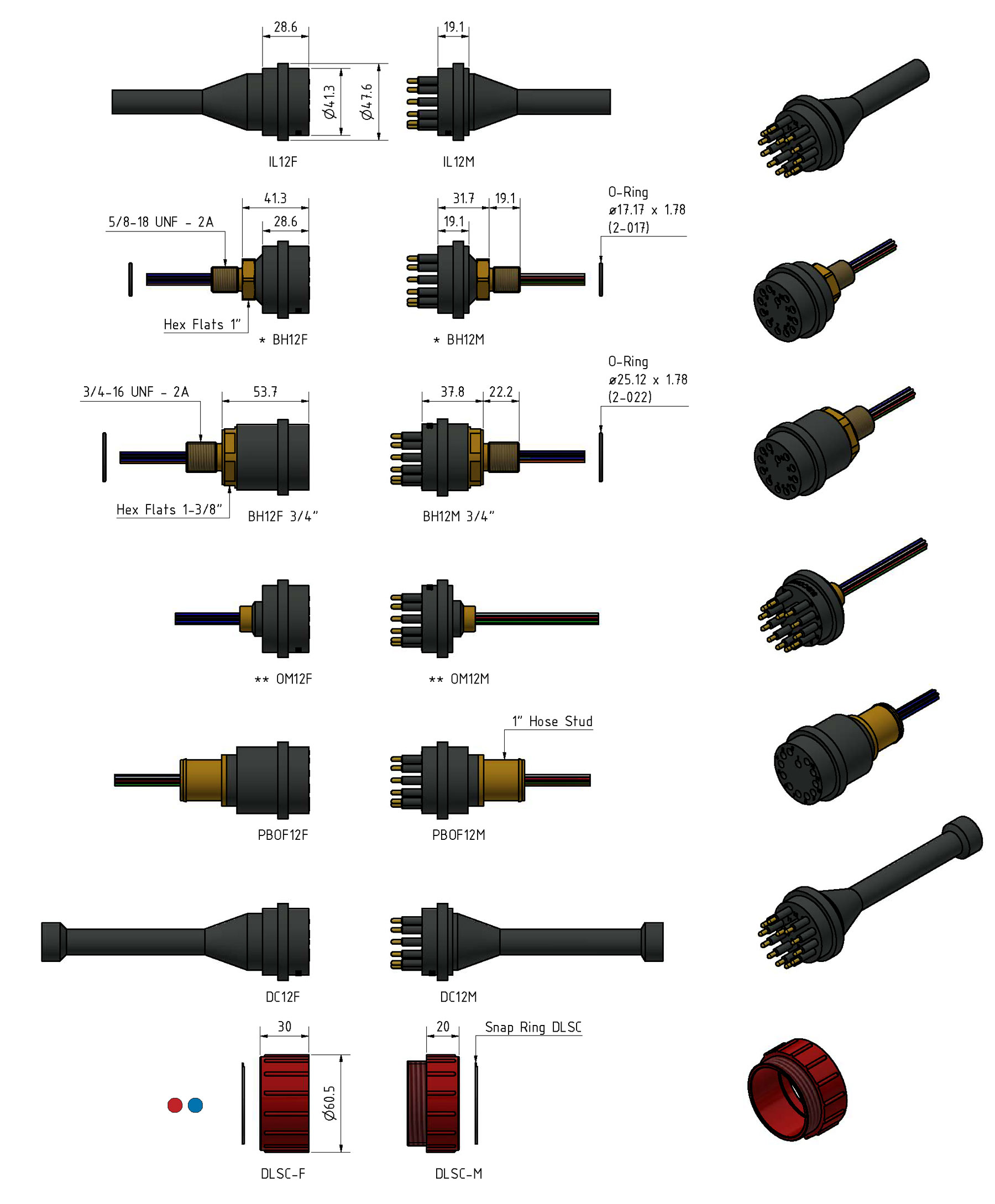

SubConn Circular - 12, 16 and 25 contacts

Request a quote for: SubConn Circular - 12, 16 and 25 contacts

Get your non-binding quote today and see how we can help.

Drawing information

Dimensions in mm (1 mm = 0.03937 inch)

Threads in inches (1 inch = 25.4 mm)

Connector specifications

- Voltage rating: 600 V DC/AC rms

- 12 and 16 contacts current rating: 10 A per contact (max 60 A per connector)

- 25 contacts current rating: 3 power contacts 10 A per contact, 22 signal contacts 5 A per contact (max 60 A per connector)

- Insulation resistance: > 200 Mohm

- Contact resistance: < 0.01 ohm

- Wet matings: > 500 (open face rated)

- Temperature rating (water): - 4 to 60˚C, 25 to 140˚F

- Temperature rating (air): - 40 to 60˚C, - 40 to 140˚F

- Storage temperature rating: - 40 to 60˚C, - 40 to 140˚F

- 12 and 16 contacts connector design depth rating: 1,400 bar, 20,000 psi

- 12, 16 and 25 contacts conn. qualified pressure tested: 800 bar, 11,600 psi

- Depth rating PEEK: 300 bar, 4,350 psi

Material specifications

- Connector body: Chloroprene rubber

- Bulkhead body: Brass, stainless steel, titanium, anodised aluminium or PEEK

- 12 and 16 contacts: Gold plated brass UNS - C36000

- 25 contacts: Contact 2, 4 and 6: gold plated brass UNS - C36000, Contact 1, 3, 5, 7 - 25: gold plated beryllium copper

- O-rings: Nitrile

- Locking sleeves: POM or stainless steel

- Snap rings: Stainless steel AISI 302

- 12 and 16 conductor inline cable (2 ft, 60 cm): 18 AWG, 0.82 mm2 synthetic rubber

- 25 conductor inline cable (2 ft, 60 cm): 3 x 18 AWG, 0.82 mm2, 22 x 20 AWG, 0.52 mm2 polyurethane

- 12 and 16 contact bulkhead and PBOF leads (1 ft, 30 cm):18 AWG, 0.82 mm2 coloured PTFE

- 25 contact bulkhead and PBOF leads (1 ft, 30 cm): 3 x 18 AWG, 0.82 mm2, 22 x 22 AWG, 0.33 mm2 white tagged PTFE

- 12 and 16 contact OM leads (3", 7 cm): 18 AWG, 0.82 mm2 coloured PTFE

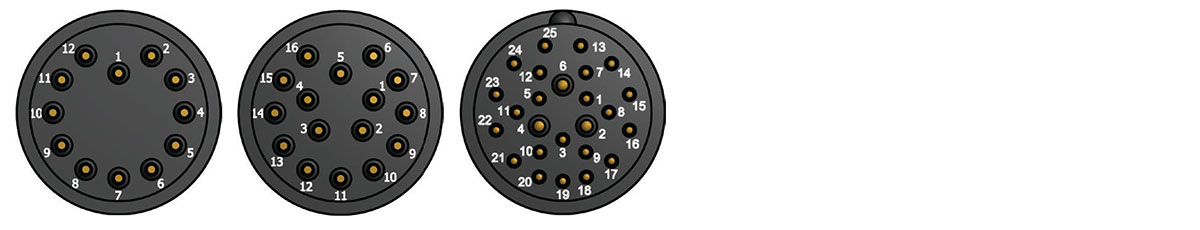

Face view (male)

Inline cable colour code for 12 and 16 conductor

1: Black

2: White

3: Red

4 Green

5: Orange

6: Blue

7: White/black

8: Red/black

9: Green/black

10: Orange/black

11: Blue/black

12: Black/white

13: Red/white

14: Green/white

15: Blue/white

16: Black/red

Inline cable colour code for 25 conductor

1: Orange

2: Black-18 AWG

3: Grey

4: Red-18 AWG

5: Green

6: Brown-18 AWG

7: Yellow

8: White/black

9: White

10: Purple

11: Blue

12: White/yellow

13: White/green

14: White/blue

15: White/purple

16: White/grey

17: White/brown/black

18: White/red/black

19: White/orange/black

20: White/yellow/black

21: White/green/black

22: White/blue/black

23: White/brown

24: White/red

25: White/orange

Nominal cable outside diameter (OD)

12 conductor cable 0.605’’, 15.4 mm

16 conductor cable 0.704’’, 17.9 mm

25 conductor cable 0.589’’, 15.0 mm

3D files

Please note that our 3D files are not 100 p.c. dimensionally stable.

If a 3D file is needed for tolerance issues, please contact MacArtney for more information.