SubConn HF Coax - 75 ohm Coax

Request a quote for: SubConn HF Coax - 75 ohm Coax

Get your non-binding quote today and see how we can help.

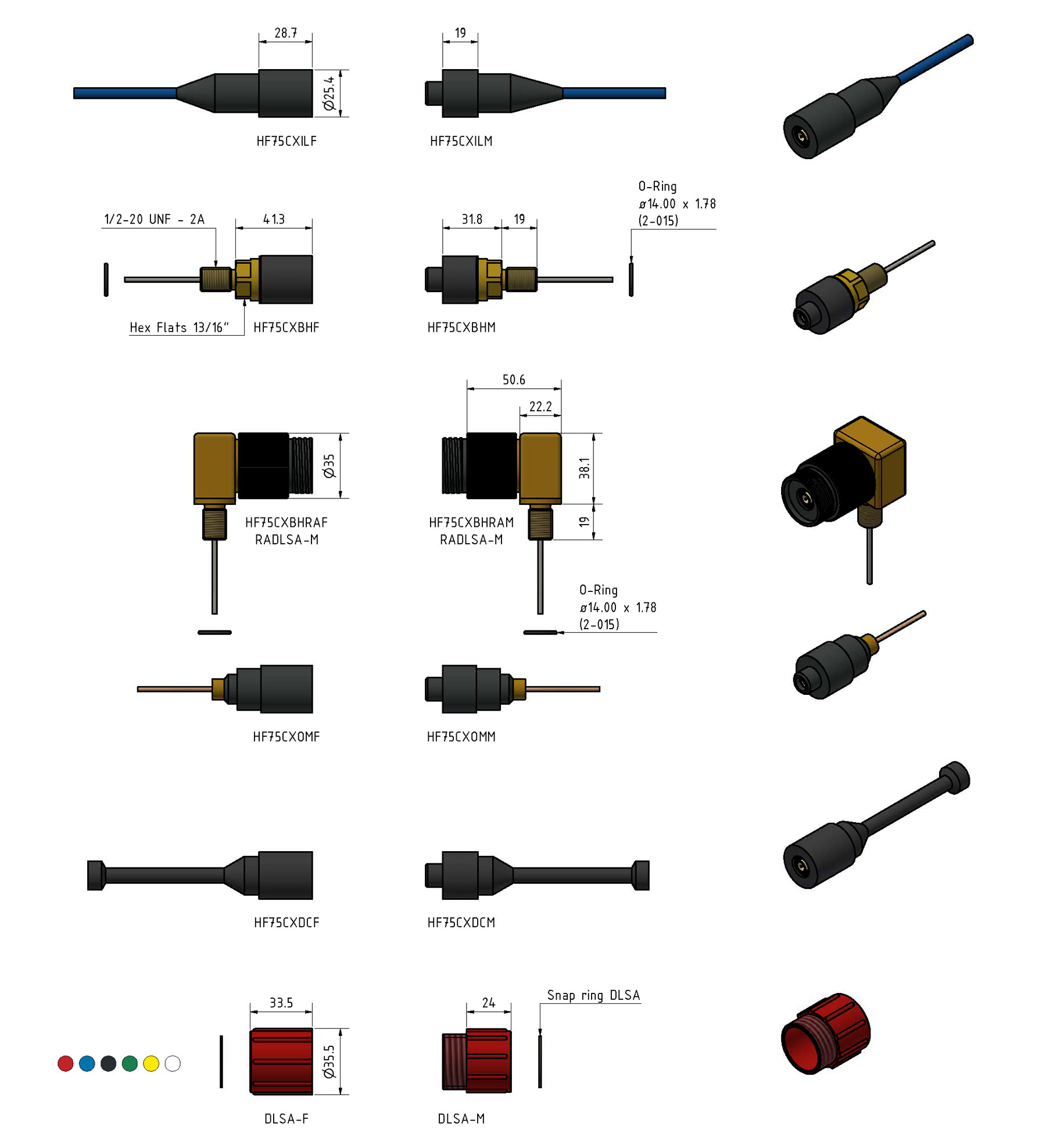

Drawing information

Dimensions in mm (1 mm = 0.03937 inch)

Threads in inches (1 inch = 25.4 mm)

Connector specifications

- Voltage rating on coax insert only: 600 V, max nominal voltage

Frequency*: 0.9 GHz / 1.2 GHz / 1.5 GHz / 1.8 GHz / 2.1 GHz / 2.4 GHz / 2.7 GHz / 3.0 GHz

Attenuation*: 6.3 dB / 7.4 dB / 8.6 dB / 9.9 dB / 11.3 dB / 12.8 dB / 14.5 dB / 15.7 dB

- Recommended max frequency: 3.0 GHz

- Insulation resistance: > 200 MΩ

- Contact resistance: < 0.01 Ω

- Temperature rating (water): - 4 to 60˚C, 25 to 140˚F

- Temperature rating (air): - 40 to 60˚C, - 40 to 140˚F

- Storage temperature rating: - 40 to 60˚C, - 40 to 140˚F

- Qualified pressure tested: 600 bar, 8,700 psi (mated)

Material specifications

- Connector body: Chloroprene rubber

- Bulkhead body: Brass, stainless steel, titanium or anodised aluminium

- Bulkhead body (RA): Brass, stainless steel, titanium or anodised aluminium

- Coax contacts: Gold plated contacts

- O-rings: Nitrile

- Locking sleeves: POM or stainless steel

- Locking sleeves (RA): RADLSA-M (black POM)

- Snap rings: Stainless steel AISI 302

- Inline cable (2 ft, 60 cm): PUR jacket cable with Mini-RG59 coax

- Coax bulkhead leads (3.3 ft, 100 cm): RG179 coax

Face view (male)

Additional information

* All frequency and attenuation values are based on a 10 meter cable assembly test including 2 bulkhead connectors (75 Ω).

BNC connector for RG179 coax leads use Amphenol 112133 or equivalent.

BNC connector for Mini-RG59 coax cable use Belden 1855ABHD3 or equivalent.

Recommended SMB termination for Coax, check in Technical Information chapter.

SubConn® Coax connectors are designed for dry mating only. The Coax series is not suitable for open-face pressure or waterblock applications. Locking sleeves are required. Avoid greasing the actual coax part.

Additional information

*All frequency and attenuation values are based on a 10 meter cable assembly test including 2 bulkhead connectors (75 ohm).

BNC connector for RG179 coax leads use Amphenol 112133 or equivalent.

BNC connector for Mini-RG59 coax cable use Belden 1855ABHD3 or equivalent.

Recommended SMB termination for Coax, see SubConn - Technical information.

Important! Dry mating only!

SubConn® Coax connectors are designed for dry mating only. The Coax series is not suitable for open-face pressure or waterblock applications. Locking sleeves are required. Avoid greasing the actual coax part.

The minimum bending radius for inline cables is 100 mm.

3D files

Please note that our 3D files are not 100 p.c. dimensionally stable.

If a 3D file is needed for tolerance issues, please contact MacArtney for more information.

3D files for download

All our 3D files are FREE of charge. Add multiple files to the file basket.