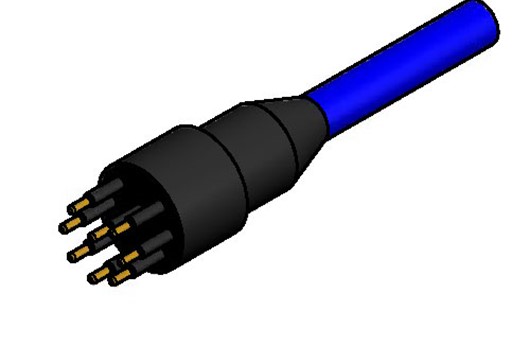

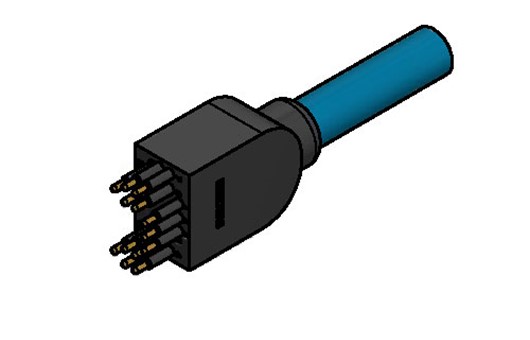

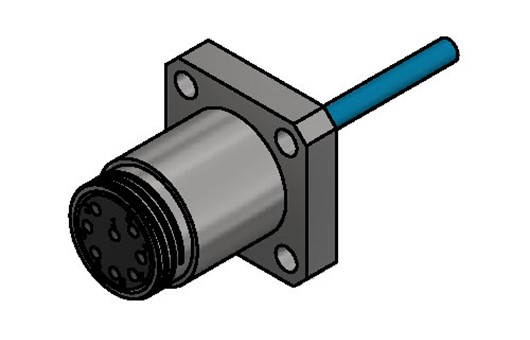

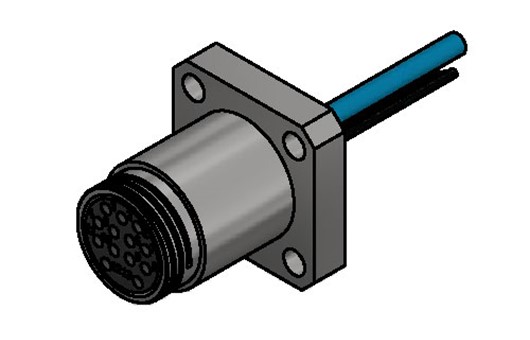

SubConn Ethernet series

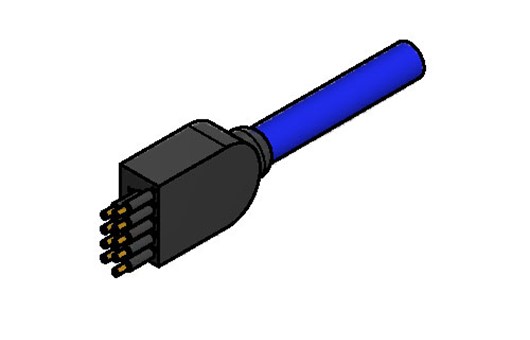

The SubConn® Ethernet series marked the first high speed underwater communications system to offer true Ethernet type performance. The series is developed and manufactured to accommodate the demand for gigabit data speed, signal and power for increasingly capable and compact underwater systems. The series includes different types of Ethernet and combined power and

Ethernet connector options in circular, metal shell and low profile configurations.

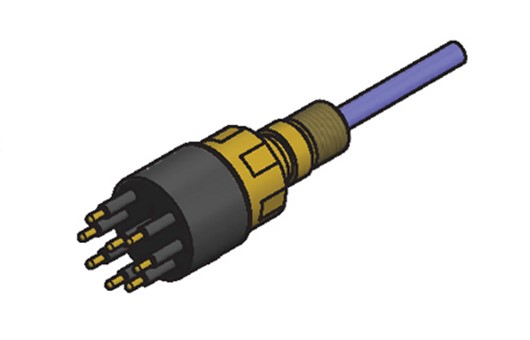

All SubConn® Ethernet connectors are capable of Gigabit speed performance and feature a high depth rating. Utilising a reconfigured version of the proven SubConn® contact and socket design, SubConn® Ethernet connectors are set to maximise data flow while eliminating cross talk and noise. With power contacts rated for 600 V at 4 A, SubConn® combined power and Ethernet connectors

allow signal and power supply to be unified in one high performance solution.

SubConn® Ethernet connectors are available with specially designed SubConn® Ethernet or combined power and Ethernet cables capable of Gigabit speed data transfer up to a distance of 75 metres. This flexible and water-resistant cable is manufactured from polyurethane (PUR). SubConn® Ethernet connectors come with colour-coded leads and are available in bulkhead, inline, Pressure

Balanced Oil Filled (PBOF) and field installable overmould versions, together with injection moulded polyoxymethylene (POM) or stainless steel locking sleeves.

Applications

- Remotely Operated Vehicle (ROV) and Remotely Operated Towed Vehicle (ROTV) systems

- Oceanographic systems, equipment and instrumentation solutions

- Offshore oil and gas, renewable energy and subsea systems

- Defence systems and equipment

- Underwater camera and video systems

- Underwater control systems

Options

- Customised harness cables and direct moulding to selected polyurethane (PUR) cables

- Customer specified cable, wire leads and bulkhead thread lengths

- Customer specified connector body material

- Certified pressure testing to specific ocean depths

3D files

Please note that our 3D files are not 100 p.c. dimensionally stable.

If a 3D file is needed for tolerance issues, please contact MacArtney for more information.